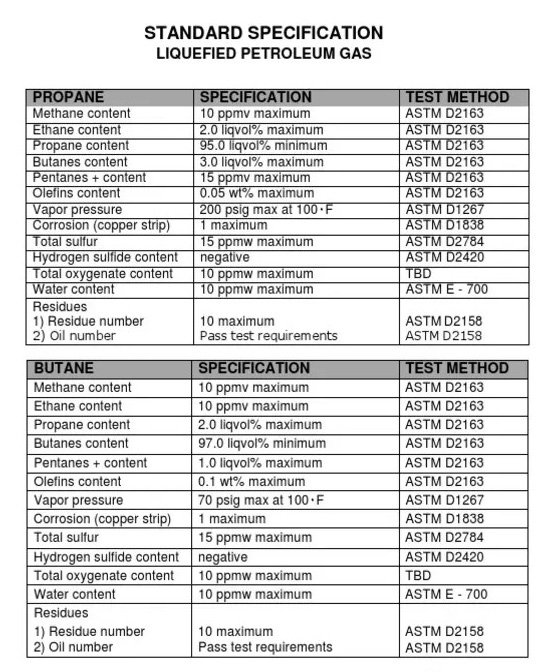

Liquefied petroleum gas (LPG) is a mixture of propane and butane, which are gases that become liquid under pressure and can then be stored in pressurised containers. The proportion of each gas varies depending on the source and climate. Prot to use. Its calorific value per unit volume is about 2.5 times larger than that of natural gas (methane). It is used for road transport, cooking, heating, refrigeration, air conditioning and in spray cans. It is a portable source of energy used for remote and leisure applications in the EU and in cooking and transport in developing countries. LPG is manufactured during the refining of crude oil (40%) or from natural gas during extraction (60%). pane is preferred where the climate is cold and butane where it is warm. LPG has a high energy per unit volume and is convenient

|

|

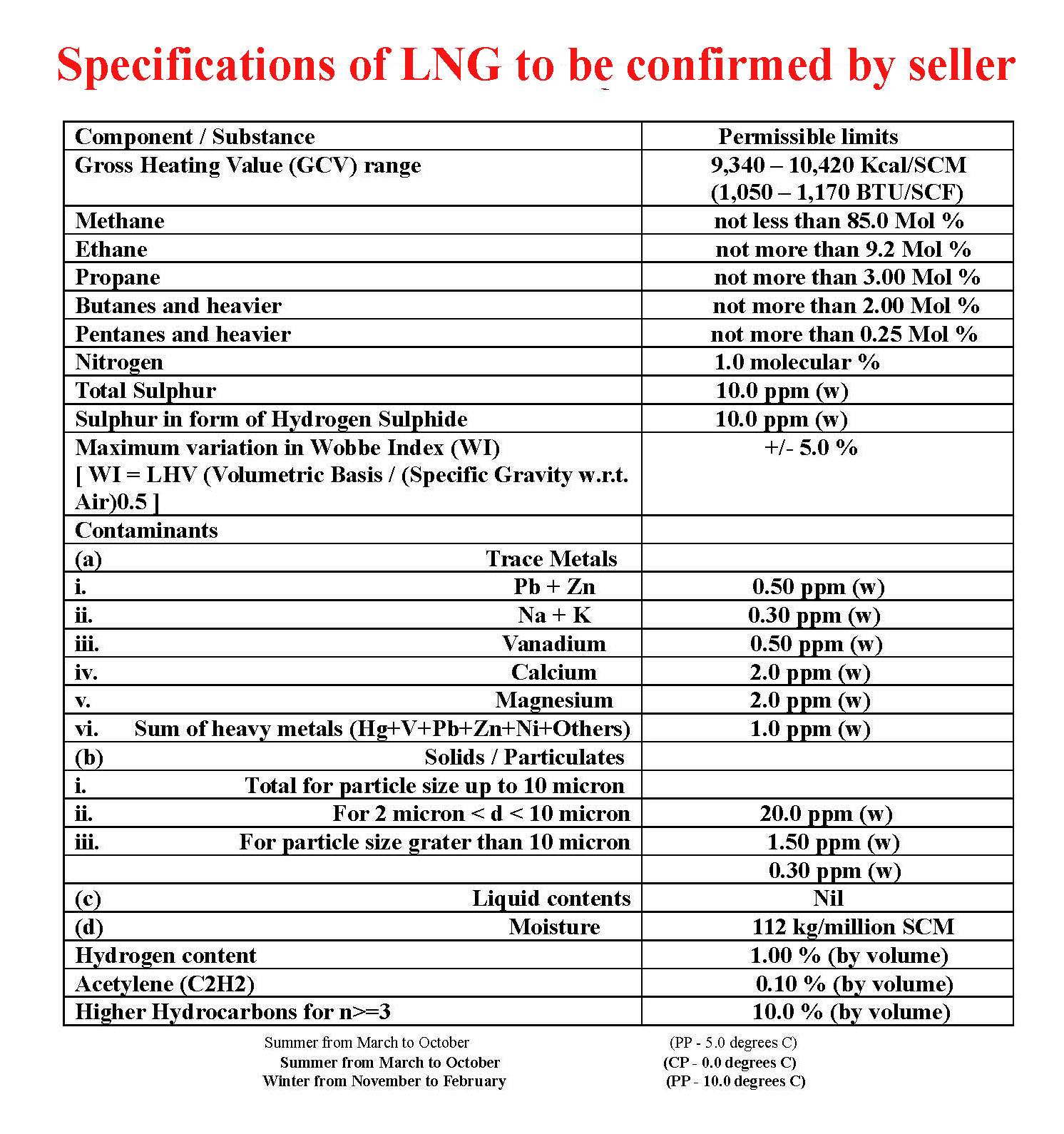

Liquefied natural gas (LNG) consists mainly of methane. Recent practice has been to liquefy the gas that is normally flared in oil fields in remote areas, but it can also be made from landfill gas when purified. LNG is about 1/614th the volume of natural gas at standard temperature and pressure, making it much more cost-efficient to transport over long distances, especially where pipelines do not exist. Similar to LPG, this portability is a major asset. LNG is used in transport and in heating and cooking as well as in industry and as a chemical feedstock.

The reliability of LPG/LNG cook stoves is generally considered high as the technology is mature and applied widely across the world . The same could be said about the supply chains for the LNG and LPG, although LNG transport could be vulnerable for security reasons. For example, IEA (2006) highlights supply problems due to hurricanes in North America. IEA (2006) also points out that the gas supply infrastructure is becoming more complex and more investment is required, in particular to increase transport skills and reduce investment costs. For importers there needs to be local distribution infrastructure development both for the fuel and for new stoves and stove conversions. Where LPG or LNG has been used in developing countries, as in the examples in China and Brazil below, then the governments in each case have subsidised the price of the gas and/or the price of conversions to burn LPG or LNG.

Although many developing countries already have access to LPG and LNG, the applicability of the technology to the rural poor is hampered by the required import facilities and distribution systems and complexities related to the poor quality of roads and relatively high per capita costs if the population density is low. The other main problem with LPG and LNG is that they can be expensive relative to other fuels and thus less attractive for the poor. In addition, the prices of LPG and LNG could be more volatile than the price of other fuels and feedstock for cooking. For example, in China, in the Fujian province, it was reported by Peoples Daily (2006) that people were switching from LNG stoves to electromagnetic stoves as LNG prices had been increased by the government. In Guangzhou, in south China, a LNG price increase resulted in some residents turning to honeycomb coal briquettes for cooking. These possible price impacts could negatively affect the affordability of the technology and LNG/LPG fuels, in particular to rural area households .

LPG is seen by the IEA as the main means for moving away from unsustainable use of biomass for cooking: the target expressed in IEA (2006) is to reduce the use of biomass in cook stoves by 50% by stimulating 1.3 billion people to switch from biomass to LPG. The future market potential for LPG could thus be huge. However, other technologies and fuels (e.g., ethanol/methanol, Biomass gasification stoves, ICS, solar-based cooking) could serve the same purpose. LPG price increases could make LPG-based cooking less accessible for the poor, particularly in the rural areas. The scope for LPG/LNG for cooking is therefore not clear in developing countries, but it seems that it will be concentrated on the middle and high income groups in urban areas.

Existing gas stove burners can be easily adapted to burn LNG and LPG. (Information sourced on the web and other avenues)

LNG and LPG provide a ‘clean’ burn with almost complete combustion of the fuel so that there are only low pollutant emissions from NOx and very low particulate or other hydrocarbon emissions. There are no quantitative figures for the overall amounts of pollutants reduced by LNG and LPG, but considering the 2.5 billion people who currently rely on biomass-based fuels in the developing world, the potential for reductions in local smoke and volatile organic compound pollution is very large. In order to get an overall perspective of the environmental benefits of LNG/LPG, a whole life cycle assessment is needed to consider the supply chains for the fuels. The supply chain for LNG requires pipelines for the gas, liquefaction plant, port facilities, and cryogenic tankers to transport the LNG where the gas is onshore. If the gas is offshore or where port facilities are not available, then floating liquefaction plants can be built. LNG plant design and LNG shipping are the other key links in the chain. The LNG is loaded directly onto ships from the production platform.

However, LPG is not commonly found in rural areas where biomass use tends to be highest and where the health effects of smoke are also highest. Nonetheless, it is used amongst middle or high income groups in urban areas of developing countries. The high initial cost of purchasing appliances and cylinders, the relatively complex technology, irregularity of supply and risk of explosion mean that it is not widely used in the majority of poorer areas of developing countries . The LPG supply chain is not practical for the poor as cylinders are usually exchanged at filling stations. Since there are not many of these in rural areas and since transport is poor, access to LPG is very difficult.

India has had an aggressive LPG promotion campaign for years and announced in February 2010 that there will be a program to provide free stoves to households below the poverty line (Energy for Development, 2010).

The overall environmental impact of fuel switching to LNG/LPG can be positive or negative in terms of GHGs depending on the efficiency of combustion and sustainability of the fuel used. However, ICS and greater combustion efficiency generally would be expected to lead to larger reductions (IEA, 2006).